Do you want to create quality printed circuit boards? Are you looking to break into the world of PCBs? Whether you’re a complete beginner or may already have some experience, this ultimate guide will provide you with all the information and tools needed to build your own high-quality circuit boards. This post will cover everything from the basics of printed circuits and layout design all the way through fabrication, assembly, and testing. If your goal is to become an expert builder of commercially viable PCBS – or you need a better understanding of what goes into their development – then get started with this guide!

Table of Contents

Understand the basics of printed circuit board design

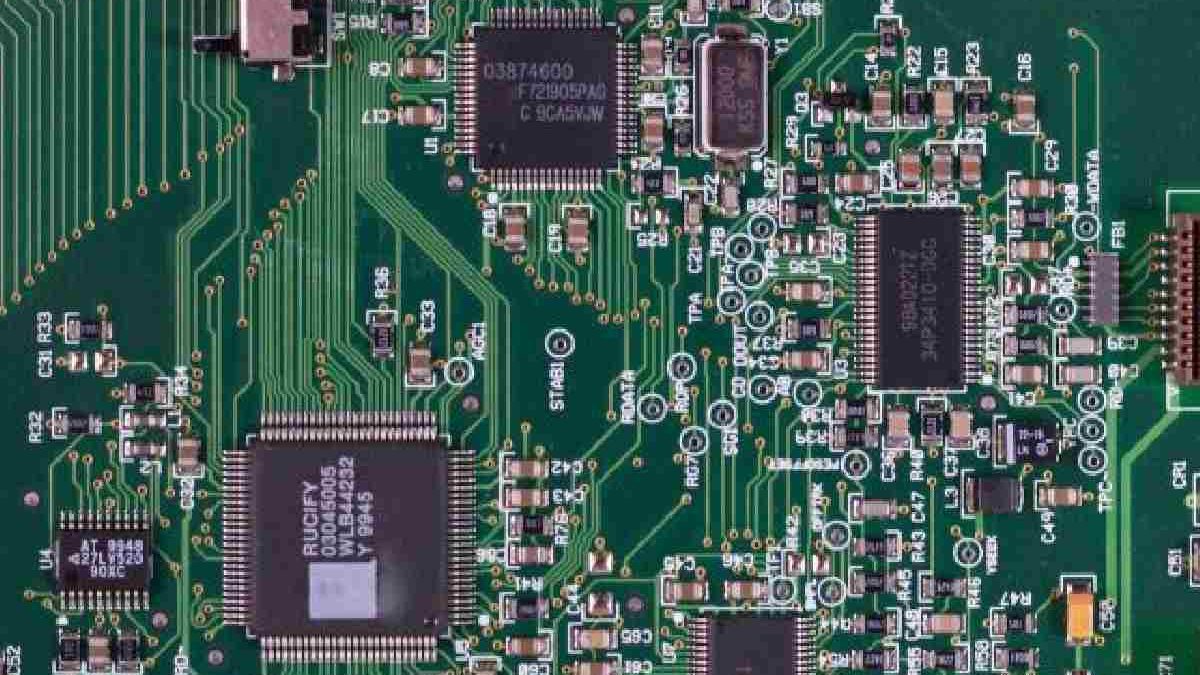

Printed circuit board (PCB) design is a fascinating field that presents many exciting challenges. For example, PCB designers must carefully examine the electrical requirements of the circuit they are designing to ensure it functions correctly and reliably. They also need to be aware of safety considerations such as avoiding short circuits and preventing electric shock hazards.

Additionally, the physical design must be optimized for size and efficiency with the right combination of components. Working out all these details to create a functioning PCB can be immensely rewarding, especially when you consider that such designs are responsible for connecting complex electronic systems together in everything from your cell phone to self-driving cars. Understanding the basics of printed circuit board design could open up a future full of exciting possibilities!

Choose the right components for your board and layout

When building a board, choosing the right components can be the difference between success and failure. It is essential to research which parts are compatible and determines what kind of performance and results you seek. While more expensive parts may guarantee higher performance, there is no substitute for understanding how your individual choices might affect the choice of the components that follows it.

This is particularly important when it comes to layout; orienting your parts to minimize negative feedback loops or interference from other nearby parts can optimize performance and troubleshoot common electrical issues. Ultimately, choosing the right components and laying them out correctly is essential for achieving an ideal board outcome.

Get the right PCD design software

Having the right PCD (Product Configuration Design) software like Altium is essential to streamline the product design process and ensure that products meet customer needs. Finding the right solution can be a challenge, however, and involves careful analysis of your design requirements, the workflow process you need to follow, and the available budget. It’s important to remember that PCD software can save time and resources by automating tedious tasks while significantly simplifying complex product configurations. Before selecting a PCD software solution provider, carefully consider your organization’s present needs and long-term objectives to get the best possible investment for your technology dollar.

Design and manufacture the PCB using an appropriate manufacturing process

The process of designing and manufacturing a Printed Circuit Board (PCB) starts with understanding the requirements of your project. This can involve any types of components that you need to include, such as electrical, mechanical, and software elements. Once the design specifications are finalized, it’s time to create the actual PCB.

Generally, this involves steel etching the copper layers onto a pre-cut FR4 substrate before attaching all components soldered into place. To ensure the highest quality results, picking an appropriate manufacturing process suited to your project’s specs is essential. Having access to experienced engineers and fabrication houses with experience in constructing boards will also be beneficial in this process.